- Necessary

- Analytics

- Targeting

Show details

The 3145 TRIDENT delivers consistent and precise results, allowing you to work faster and with higher quality.

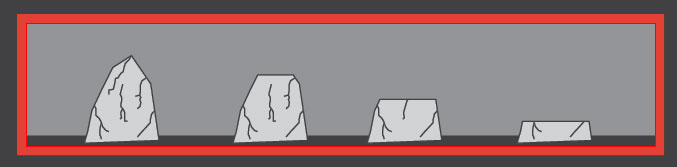

Most manufacturers today use silicon carbide or aluminum oxide for producing sanding discs, and nearly 90% of abrasive products on the market are made from these two materials. Among them, silicon carbide discs stand out due to their structure—they are significantly sharper and more aggressive than aluminum oxide discs, making them more effective for fast and efficient material removal.

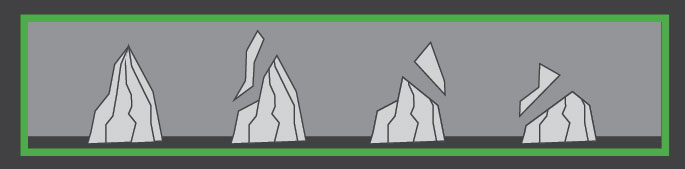

The effectiveness of 3145 TRIDENT discs lies in their pyramid-structured carborundum (silicon carbide) grains, which fracture in a controlled manner during use. This continuously exposes fresh, sharp cutting edges, meaning the disc remains sharp throughout the entire sanding process.

Self-sharpening minerals constantly reveal new, sharp surfaces during sanding, resulting in faster and more uniform cutting.

Conventional abrasives lose their sharp edge with use.

Engineered for Precision and Efficiency

The multi-layer construction of the 3145 TRIDENT combines electrostatically coated silicon carbide grains with a flexible PET film and foam backing. This design enables both dry and wet sanding, while delivering fast, controlled cutting and a smooth glide with added cushioning for sensitive surfaces.

The 3145 TRIDENT is ideal for automotive tasks, such as removing scratches and minor surface imperfections on clear coat or paint, making it perfect for use in the final stages of surface preparation or repair before polishing.

The discs are available in two sizes: 150 mm and 75 mm.